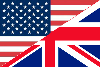

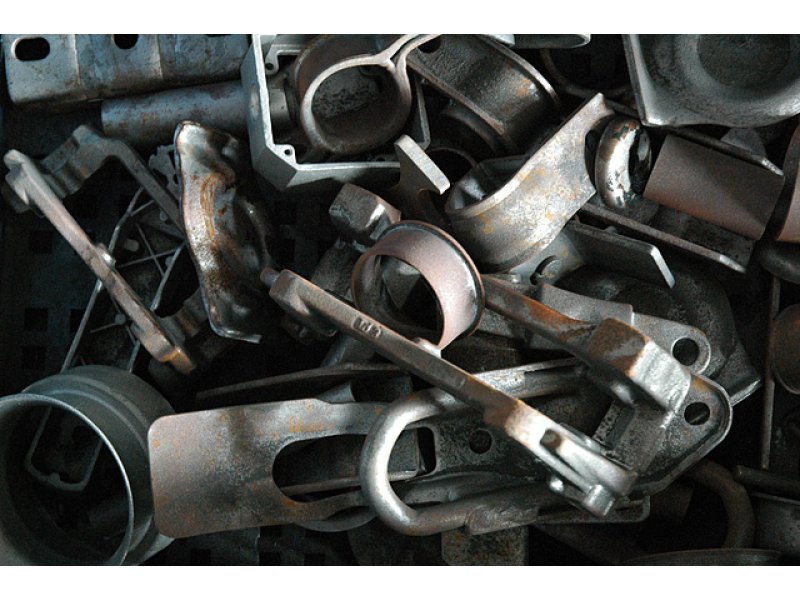

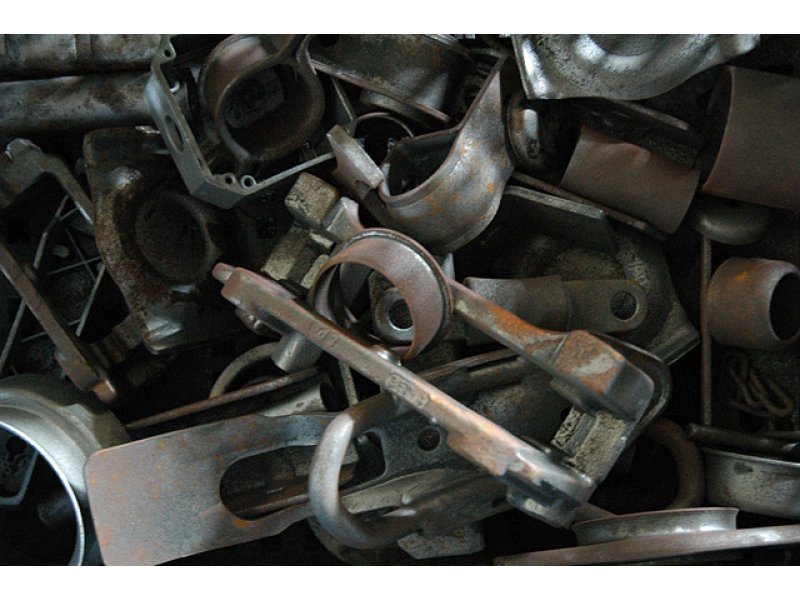

Surfaces that have not undergone shotblasting typically contain defects such as rust, corrosion, burrs, oil, and remnants of old coatings, which usually arise from manufacturing processes or environmental conditions.

These defects negatively affect the success of processes such as coating, painting, or galvanizing, weakening aesthetics, durability, and adhesion performance. Surfaces of this type are generally classified as C and D according to the ISO 8501-1 standard, and because they do not provide a smooth adhesion surface, they can cause coatings to peel or detach over time.

Our images of unblasted surfaces clearly reveal these deficiencies, emphasizing the critical importance of the shotblasting process.