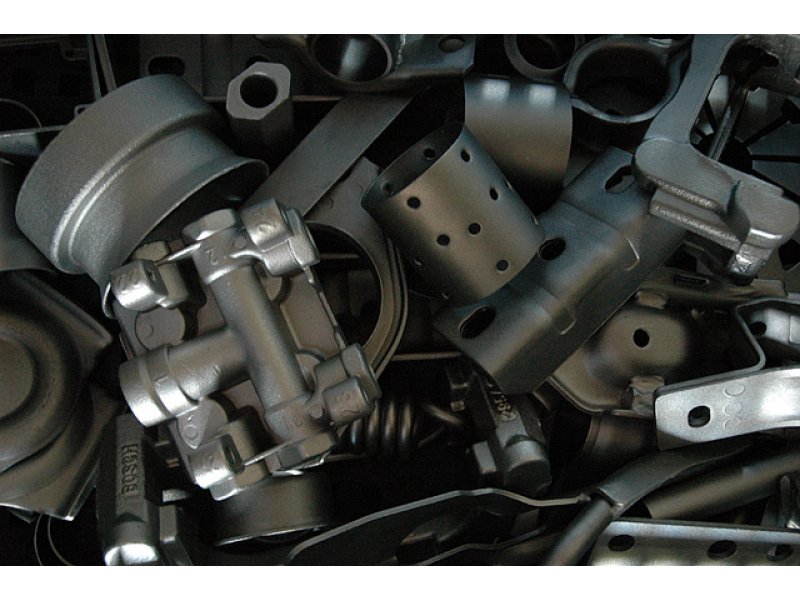

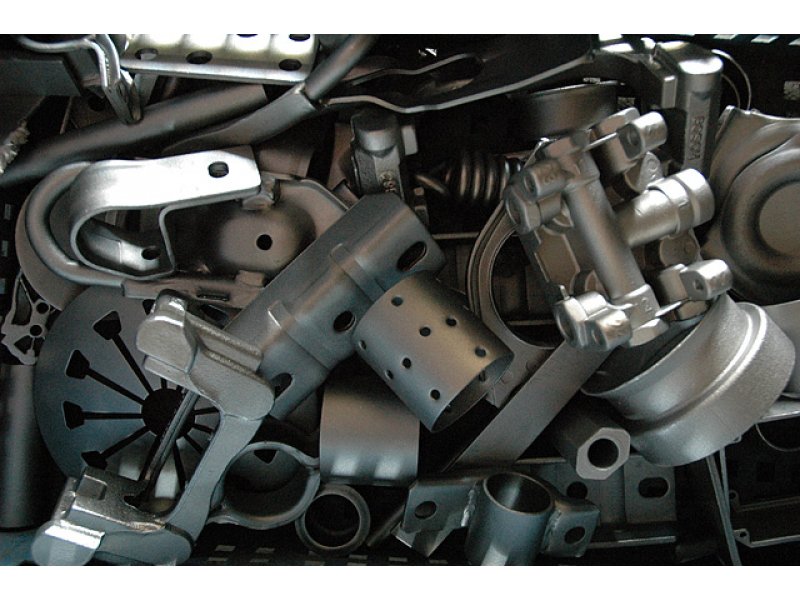

After shotblasting, surfaces typically reach Sa 2.5 (Near-White Metal Cleanliness) level according to the ISO 8501-1 standard, with all rust, oxide layers, paint residues, and other foreign materials completely removed. This process creates a uniform clean surface and an ideal roughness profile, providing an excellent adhesion substrate for coating, painting, or galvanizing operations.

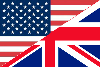

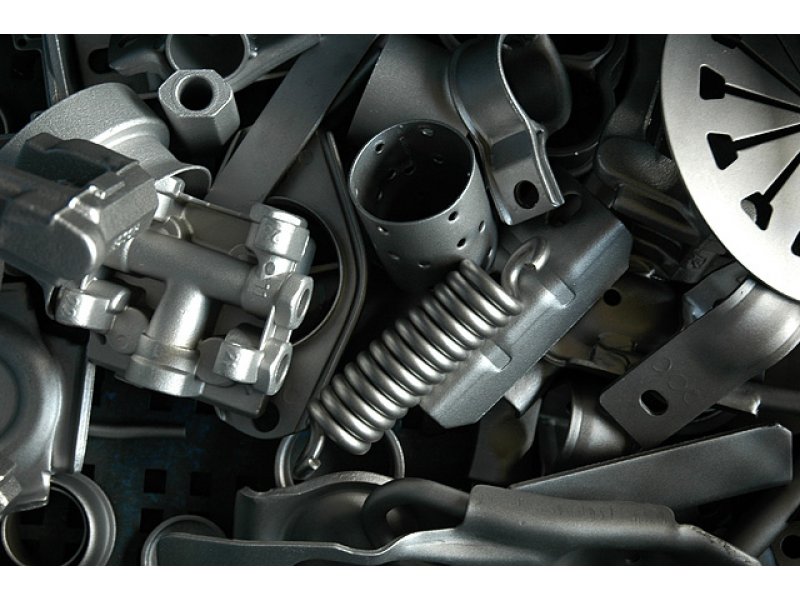

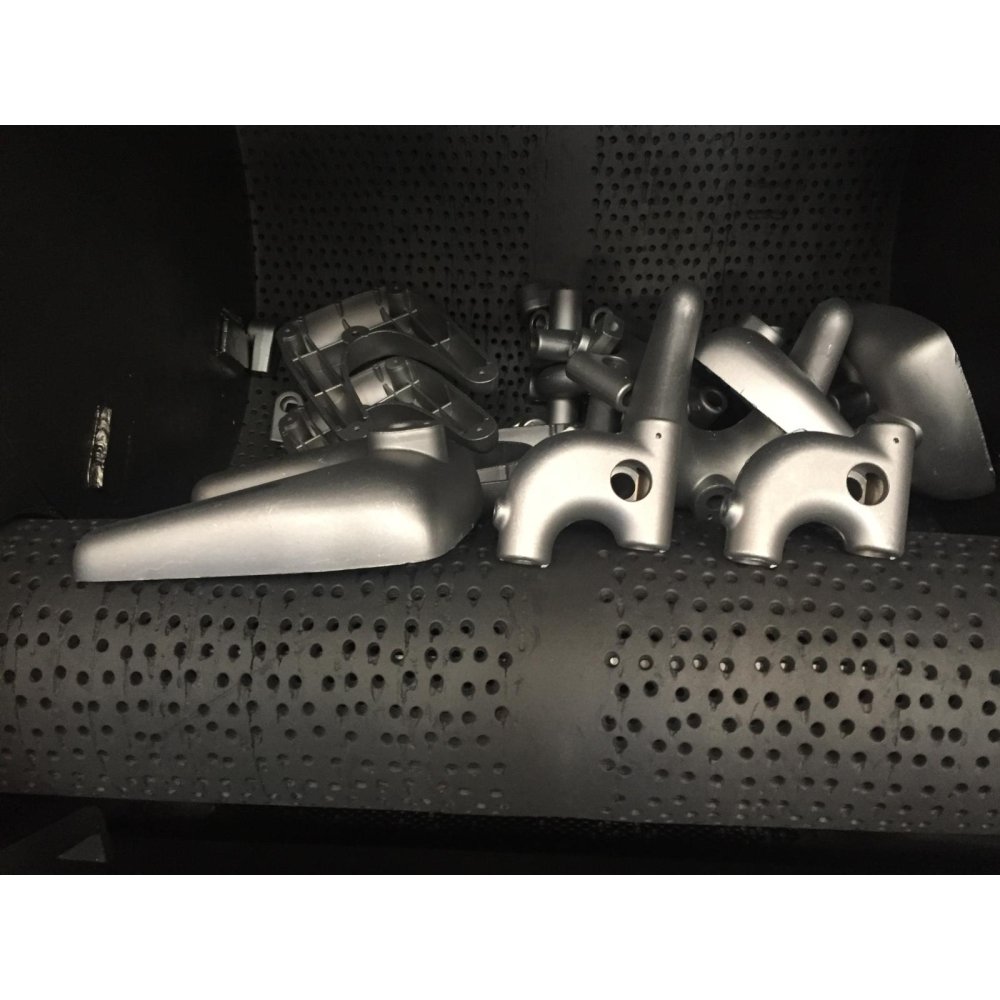

Our images of shotblasted products clearly demonstrate the superior surface quality achieved after the process and how the prepared adhesion surface contributes to product durability and aesthetic appearance.