Areas of Use

Automatic drum sandblasting machines provide continuous and uninterrupted surface cleaning while minimizing operator intervention. Integrated sand feeding and recovery systems increase efficiency while reducing energy consumption.

These machines are commonly used for surface smoothing of sheet metal parts coming out of the press, preparation before painting and rubber coating, scale cleaning of hot forged parts, revision of old parts, surface treatments of aluminum injection casting and brass forged parts, and stress relief processes of compression springs.

To prevent personnel errors and work losses, loading, unloading, and door mechanisms are fully automated. Thanks to the PLC-controlled system, all processes are managed automatically, and the machine control panel offers automatic, semi-automatic, and manual operation options.

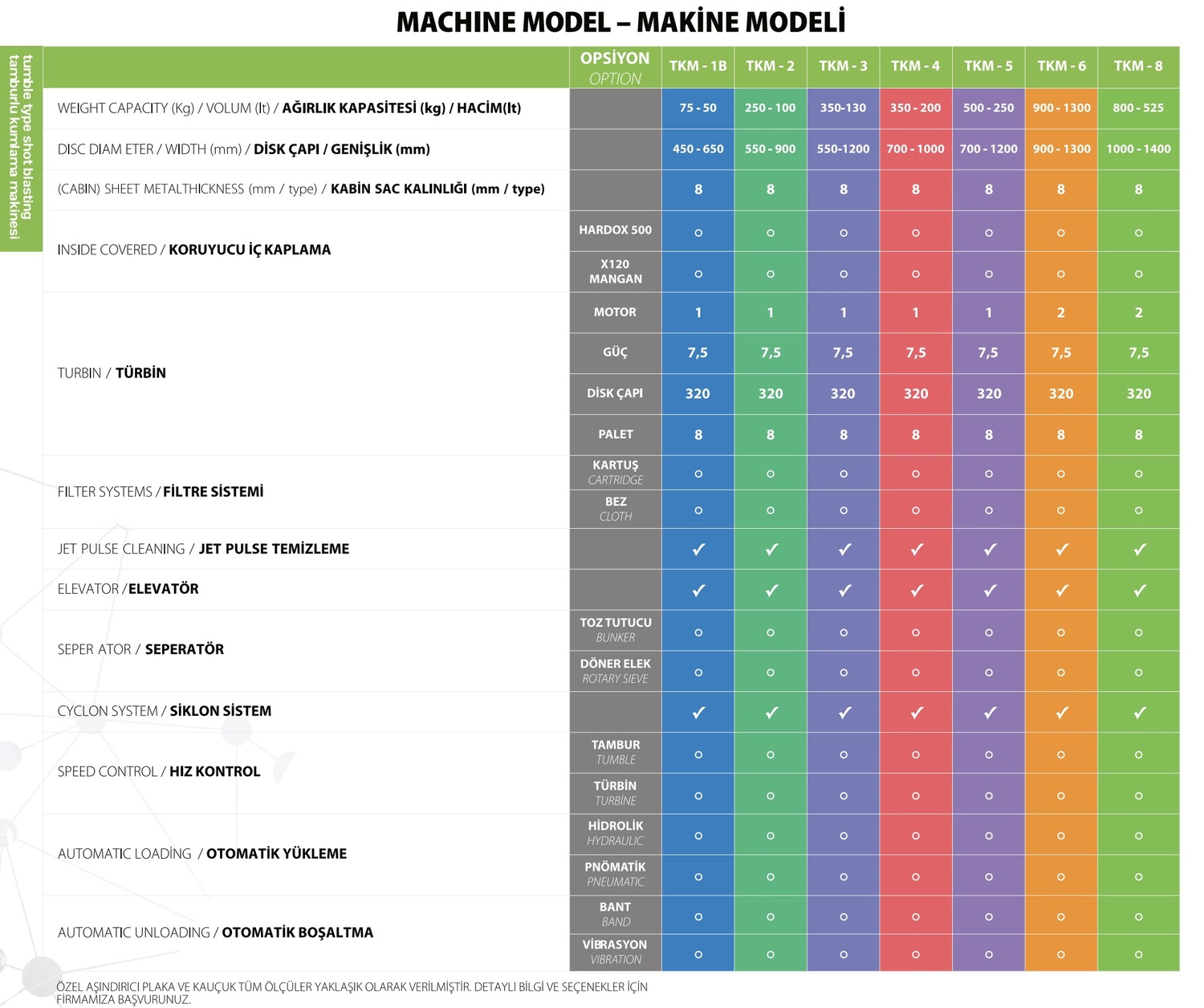

Various capacity and size machine options are available to suit different workload intensities.